1.What material is used for large diameter water pipes?

The common materials used for large diameter water pipes are carbon steel, ductile iron, stainless steel, and PVC. The choice of material depends on factors such as the availability of the material, the cost, the durability, the required pressure rating, and the environmental conditions.

For example,carbon steel is usually a commonly used material for large diameter water pipes due to its various advantages. Some of the advantages of carbon steel water pipes include:

Durability: Carbon steel pipes are highly durable and can withstand high pressure, making them ideal for use in water supply systems.

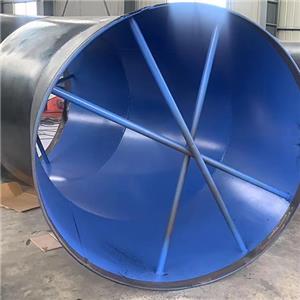

Corrosion resistance: Carbon steel pipes can be treated with coatings and linings to enhance their corrosion resistance, ensuring that they last longer and require less maintenance.

Cost-effective: Carbon steel pipes are relatively inexpensive compared to other materials, making them an attractive option for large-scale water supply systems.

High strength: Carbon steel pipes have high tensile strength and are resistant to deformation and cracking under stress, making them suitable for use in high-pressure applications.

Recyclable: Carbon steel is a recyclable material, making it an environmentally friendly choice for large diameter water pipes.

Overall, carbon steel water pipes are a cost-effective and durable option for large diameter water supply systems, especially when considering their strength, corrosion resistance, and recyclable.